Help Center

-

FAQs

-

Velocity View

-

Velocity Office

-

-

- Add Job Cost Transactions

- Add Payroll Transactions

- Build Sheet

- Custom Location Barcodes

- Export to QB

- Move Transactions

- Non-Inventory Charges

- Parts – Parts Request

- Parts – Print Item Barcodes

- Parts – Remote Inventory

- Parts – Scan Parts

- Quality Score

- Review Job Cost Transactions

- Review Payroll Transactions

- Scheduling

-

- Build Assemblies Min Max Planning

- Build SOS Forms

- Customer Balances Report

- Customer Invoices

- Inventory Transaction Detail

- Invoice Detail

- Item Ordering Report

- Job Cost Labor

- Job Status

- Location Barcodes

- Part Requests Report

- Parts – Reorder Report

- Payroll

- Payroll vs Costing

- Production Hours

- Profit

- Sales Pipeline Report

- Sales Receipt – Invoice Detail Discrepancies

- Sig Series Journal

- Stock Inquiry Report

- TBO Report

- Show Remaining Articles (6) Collapse Articles

-

- Action Board

- Build Sheet Categories

- Build Sheet Templates

- Build Types

- Colors

- Customer Portal Users

- Edit Inventory Locations

- Employee Departments

- Employees

- Employees Read-Only

- Job Locations

- Jobs

- Labor Codes

- Lines

- Menu Security

- Parts – Order Parts Categories

- Posting Classes

- Pre-Ship Template Items

- Request Locations

- Request Reasons

- Reset Build SOS

- Routing Departments

- Sales and Marketing URLs

- Security Group Permissions

- Security Groups

- Slack Routing

- Slack Users

- SOS Build Forms

- SOS Forms Labor Code Mapping

- SOS Master Forms

- Users

- Show Remaining Articles (16) Collapse Articles

-

-

-

Velocity App

Table of Contents

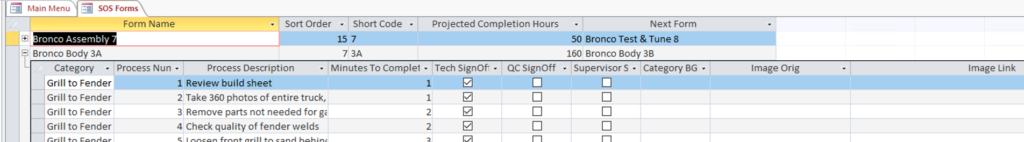

SOS Master Forms

Print

PostedMay 12, 2023

UpdatedSeptember 13, 2023

Overview

Each Form has a set of associated process steps that should be completed in order. This datasheet is where the master set of forms and processes are created and edited by Admin. Some (most) changes made here are automatically propagated to existing builds.

A copy of the master SOS (Standard Operation Specifications) processes are copied to each Build in order to maintain the consistent procedures needed to maintain a high level of quality.