Help Center

Build Assemblies Min Max Planning

Overview

The Build Assemblies Min Max Planning report is used by inventory purchasing managers to determine how much inventory is needed based on work in progress or planned Builds.

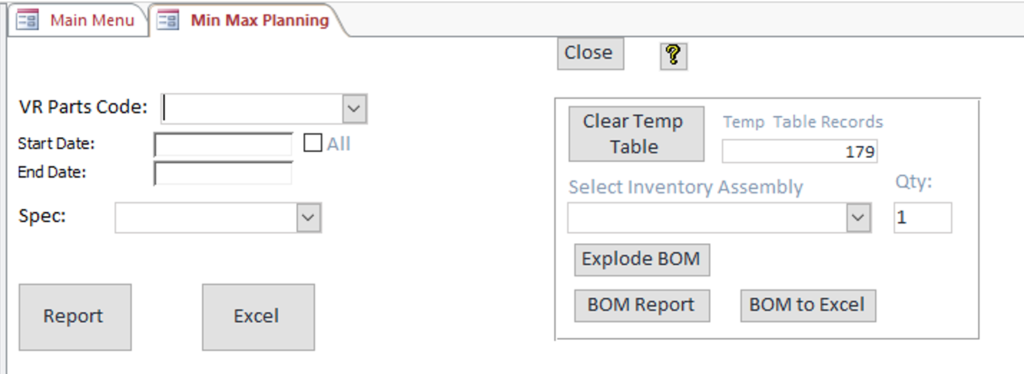

The right-side of the form allows a user to enter a series of Inventory Assembly parts and then exploded them to the raw parts required to produce the kits or assemblies.

The following procedure should be used to create the raw parts list. It uses a temporary table, thus Velocity data is left unaffected.

- The Clear Temp Table button should be clicked at the start of each session. The table is local to the users machine. If they close and restart the application the temp table will be cleared. However, if they close the form, may be to look some thing up, then reopen the form the temp table will not be cleared. This is by design.

- Select an Inventory Assembly, then enter the quantity desired for that assembly. (Leave the default at 1 if you just want to see what it takes to make a single assembly.)

- Click Explode BOM to add the raw materials needed for the selections of step 2.

- Continue to Select and Explode assemblies until all desired items have been exploded.

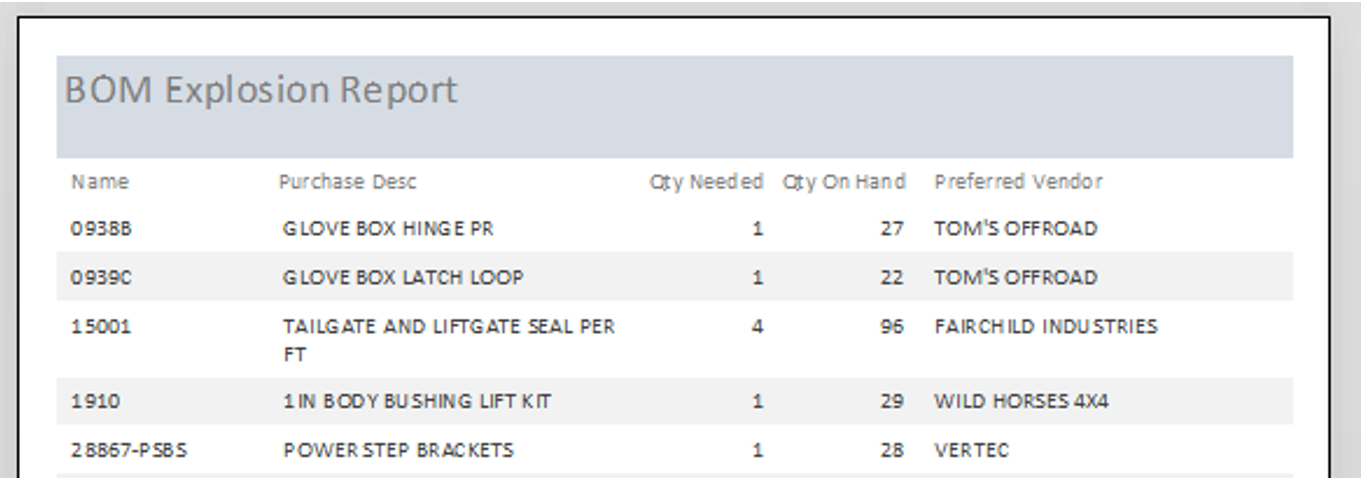

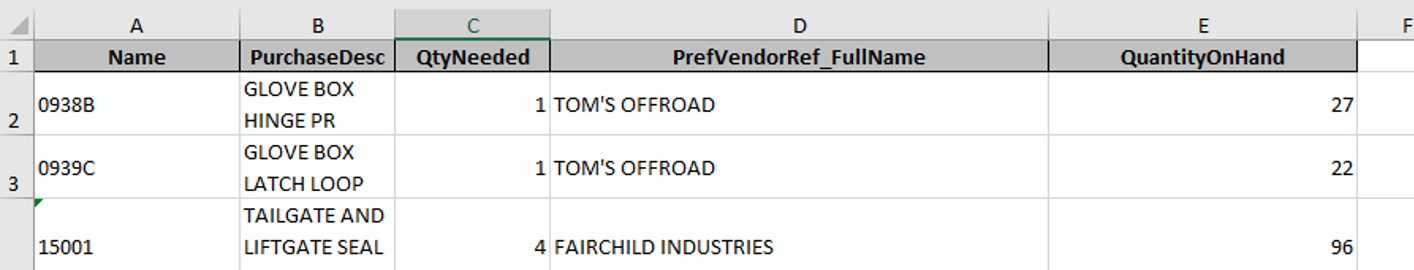

- BOM Report will print a list of all the raw materials needed to produce the parts.

- BOM to Excel will open an Excel spreadsheet with all the raw materials list. It can be used to cut and paste the details into another spreadsheet.

Features

VR PARTS CODE – List is from the Quickbooks custom field.

SPEC – List is from the Quickbooks custom field.